Mica Insulated Band & Strip Heaters

- EXCEL�s Mica Band Heaters are widely used to heat the molds, dies, nozzles and especially to heat the cylinders (barrels) on all types of�plastic(s) processing machinery

- The mica heater is most economic

- It provides excellent thermal conductivity as heat transfer is by �conduction�

- Due to its best heat transfer capability, faster heating up & cooling down is possible

- Maximum sheath temperature upto 480�C (900�F)

- Maximum watt density = 25 watts/square inches

- Note: In case where high watt densities are require, it is important that All �heaters should be used with appropriate, approved and precise �temperature control/sensor device(s)

- The built in insulation is specially formulated for the excellent heat �reflection &performance capabilities

- The low mass heaters give the best controllability. The lower the thermal �mass, lesser time required to deliver the heat to the object to be heated. �Due to low mass and high conductivity, the�Polymer Melt� is heated �quickly. Resulting autotune function on a control works best.

- Flexible one or two � piece design makes installation faster & easier . Its �flexible construction also allows the heater to be opened to the full �diameter of the cylinder

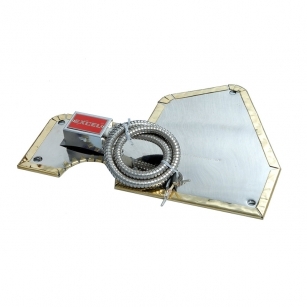

- The most common square, rectangular and hex-shaped mica heaters can be manufactured as per your specifications in one or two piece units. Available with leads�or terminals

- EXCEL�s exclusive method of designing, maximizes the element wire coverage of the heated area. This results in uniform heat distribution & longer heater life

- The heater meets progressive requirements of the plastic processors

-

Technical Specifications